| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Brand Name : QIHAI

Model Number : QH-6020L

Certification : ISO, CE

Place of Origin : Foshan, Guangdong, China

MOQ : 1 Set

Price : Negotiable

Payment Terms : T/T

Supply Ability : 100 set/month

Delivery Time : 50 days

Packaging Details : wood, plastic, container

Graphic format supported : DXF,AI,BMP,PLT,DWG

Cnc or not : Yes

Application : Laser Cutting,Suitable for metal sheets cutting,cheap laser metal cutting machine,metal cutting

Cutting thickness : Materials,0-30mm,Depends,7-8,1-12 m (carbon steel)

Cooling mode : Water Cooling

Warranty : 1 Year

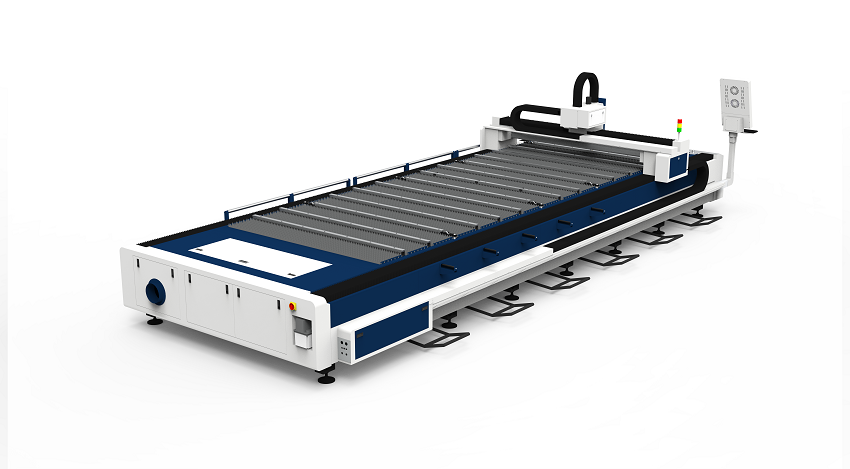

Cutting area : 6000mm*2000mm

After-sales service provided : Engineers available to service machinery overseas

Function : Cutting Metal Materials,Wifi wireless control,Cutting Metal sheet tube

Cooling system : water cooling

Beveling Core: 0°-45° adjustable angles (±0.5° accuracy), supports V/U/Y/X-type bevels; ±0.03mm dual-axis accuracy ensures uniform bevel quality.

Auto Material-Lifting: Handles up to 1000kg workpieces, protects surfaces, stabilizes positioning for large-sheet beveling (6000×2000mm area).

Key Specs: 1500W-20KW laser power (0.5-30mm thickness), 100m/min max speed, double rack & pinion servo transmission.

Fit: Steel structures, pressure vessels — ideal for large-scale welding prefabrication.

| Processing Area | 6000 * 2000mm |

| Maximum Loading Weight | 1000kg |

| Machine Weight | 3600kg |

| Overall Dimensions | 8000×2760×1900mm |

| Laser Power Range | 1500W - 20KW |

| X/Y-axis Positioning Accuracy | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.03mm |

| Maximum Linkage Acceleration | 1.0G |

| Maximum Linkage Speed | 100m/min |

| Transmission System | Double rack & pinion transmission with servo drive |

| Voltage Requirement | 380V |

| Frequency | 50Hz |

Advantage

High-Precision Beveling Reduces Welding Prep Time: The ±0.03mm X/Y-axis accuracy (paired with double rack & pinion servo drive) ensures consistent bevel angles (0°-45°, ±0.5° error) across the entire 6000×2000mm processing area. This eliminates the need for post-bevel grinding (a common step with lower-precision machines), cutting welding prefabrication time by 40%-60% and ensuring tight weld joint fits.

Auto Material-Lifting Optimizes Beveling for Large Sheets: For heavy workpieces (up to 1000kg) that are impractical to manually reposition, the automatic lifting system adjusts material height without surface damage — critical for multi-angle beveling (e.g., double-sided V-bevels on 6m-long steel plates). It eliminates labor risks and ensures stable material placement during high-speed beveling (100m/min), avoiding angle deviations caused by manual movement.

Broad Power Range Adapts to Diverse Beveling Needs: The 1500W-20KW laser power covers 0.5-30mm metal thicknesses — from thin aluminum (0.5-2mm) requiring delicate Y-bevels to thick carbon steel (20-30mm) needing deep X-bevels. The adjustable power ensures optimal energy input for each material, preventing over-melting (which ruins bevel edges) or under-cutting (which requires rework).

Sturdy Build Guarantees Continuous Beveling Reliability: The 3600kg heavy-duty frame dampens vibration during high-acceleration (1.0G) beveling, ensuring consistent precision even during 8+ hours of continuous operation. This stability is vital for large-batch projects (e.g., pressure vessel components) where bevel uniformity across hundreds of workpieces directly impacts welding quality and safety.

|

|

Beveling Cutting Automatic Material Lifting Sheet Metal Laser Cutting Machine Images |