| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Brand Name : QiHai

Model Number : QH-3015F

Certification : CE, ISO

Place of Origin : Foshan, Guangdong, China

MOQ : 1 set

Price : Negotiable

Payment Terms : T/T

Supply Ability : 90set/mon

Delivery Time : 45-60 work days

Packaging Details : wooden box

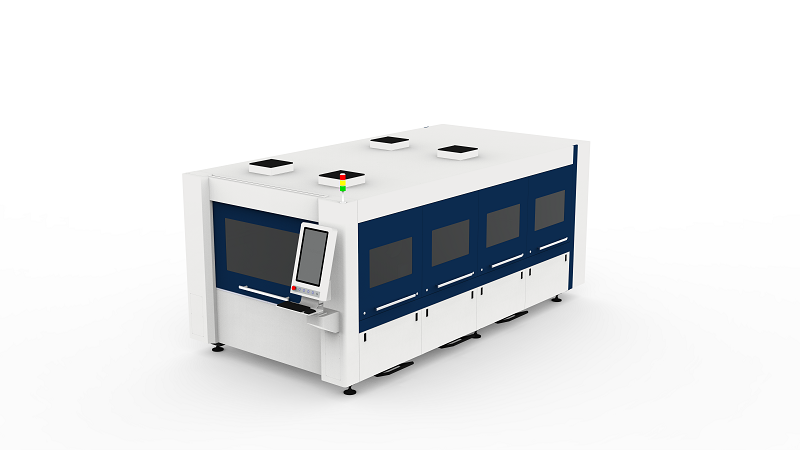

Product : Sheet Metal Laser Cutting Machine

Processing Area : 3000 * 1500mm

Laser Power : 6000W-20000W

X/Y-axis Positioning Accuracy : 0.03mm

Frequency : 50Hz

Voltage : 380V

Laser Generator Classification : Fiber Laser Generator

Transmission : Double rack&pinion transmission and servo drive

Working Environment : 0-40℃, Humidity ≤80%

Graphic Format : PLT, DXF

Lathe Structure : Tube Sheet Welding

Longitudinal Core Advantage: 3000mm longitudinal processing length optimized for elongated workpieces; longitudinal-oriented single platform ensures stable support and precise positioning for long sheets.

Key Specs: 3000×1500mm (longitudinal-focused) area, 800kg max loading, ±0.03mm longitudinal axis accuracy, 100m/min max linkage speed, 6000W-20KW power.

Fit: Long-size sheet metal tasks (automotive longitudinal parts, large cabinets); workshops needing longitudinal precision + full enclosure safety.

| Processing Area | 3000 * 1500mm |

| Maximum Loading Weight | 800kg |

| Machine Weight | 1800kg |

| Overall Dimensions | 4800 * 2350 * 1900mm |

| Laser Power Range | 6000W - 20KW |

| X/Y-axis Positioning Accuracy | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.03mm |

| Maximum Linkage Acceleration | 1.0G |

| Maximum Linkage Speed | 100m/min |

| Transmission System | Double rack & pinion transmission with servo drive |

| Voltage Requirement | 380V |

| Frequency | 50Hz |

Advantage

Longitudinal Structure Fits Long-Size Workpiece Needs: The 3000mm longitudinal processing dimension eliminates the need for splicing long workpieces (e.g., 3m-long stainless steel sheets), reducing material waste and post-processing time. The longitudinal-optimized double rack & pinion transmission minimizes precision loss during long-distance movement—ensuring ±0.03mm accuracy even when cutting 3m-long continuous features (e.g., linear slots, long holes), which is critical for applications like automotive frame components requiring consistent longitudinal tolerance.

Longitudinal Single Platform Boosts Operation Efficiency: Unlike non-longitudinal platforms that struggle with awkward handling of elongated sheets, the QH-3015FC’s longitudinal single platform allows smooth loading/unloading of long workpieces (e.g., sliding 3m sheets along the longitudinal axis without edge damage). Optional longitudinal material feeding racks can be paired to enable continuous feeding of long coils or sheets, cutting workpiece transfer time by 25%-30% compared to traditional non-longitudinal single-platform models.

Longitudinal + Full Enclosure Synergy Enhances Stability: The longitudinal structure, combined with the full enclosure, creates a stable processing environment for long-distance cutting. The enclosure reduces cross-wind interference that often disrupts laser focus during longitudinal long-range processing, while the longitudinal platform’s uniform 800kg loading capacity prevents sagging of heavy long sheets—ensuring consistent cutting depth and edge quality across the entire 3000mm longitudinal length. Additionally, the enclosure’s longitudinal dust-collection ports target debris generated during long-size cutting, keeping the longitudinal transmission system clean and extending its service life.

|

|

High Power Longitudinal Single Platform Fully Enclosed Sheet Metal Cutting Machine Images |