| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Brand Name : QiHai

Model Number : QH-3015F

Certification : CE, ISO

Place of Origin : Foshan, Guangdong, China

MOQ : 1 set

Price : Negotiable

Payment Terms : T/T

Supply Ability : 90set/mon

Delivery Time : 45-60 work days

Packaging Details : wooden box

Product : Sheet Metal Laser Cutting Machine

Processing Area : 3000 * 1500mm

Laser Power : 1500W-20000W

X/Y-axis Positioning Accuracy : 0.03mm

Frequency : 50Hz

Voltage : 380V

Laser Generator Classification : Fiber Laser Generator

Transmission : Double rack&pinion transmission and servo drive

Working Environment : 0-40℃, Humidity ≤80%

Graphic Format : PLT, DXF

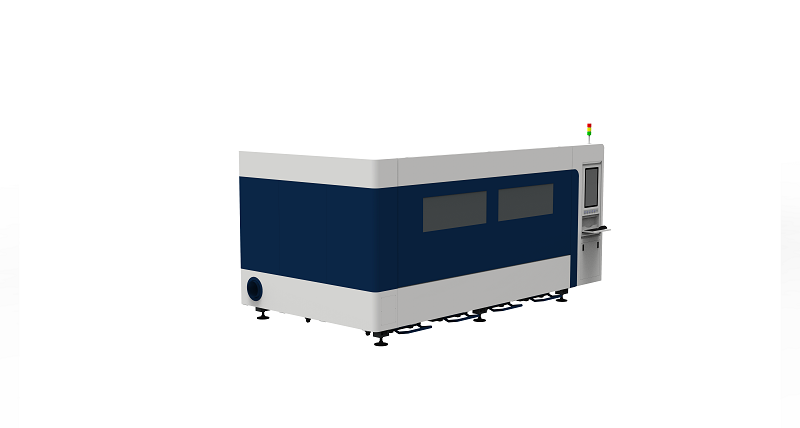

Single Platform Fully Enclosed Core: Single-platform design for easy workpiece handling; full enclosure blocks laser radiation, dust, and noise—meets industrial safety standards.

Key Specs: 3000×1500mm processing area, 800kg max loading, ±0.03mm dual-axis accuracy, 100m/min max linkage speed, 1500W-20KW laser power.

Fit: Workshops prioritizing safety (full enclosure) and operational simplicity (single platform); suits medium-batch carbon steel/stainless steel cutting.

| Processing Area | 3000 * 1500mm |

| Maximum Loading Weight | 800kg |

| Machine Weight | 1800kg |

| Overall Dimensions | 4800 * 2350 * 1900mm |

| Laser Power Range | 1500W - 20KW |

| X/Y-axis Positioning Accuracy | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.03mm |

| Maximum Linkage Acceleration | 1.0G |

| Maximum Linkage Speed | 100m/min |

| Transmission System | Double rack & pinion transmission with servo drive |

| Voltage Requirement | 380V |

| Frequency | 50Hz |

Advantage

Single Platform Simplifies Operation & Ensures Precision: The single-platform structure eliminates complex multi-platform switching, reducing workpiece positioning errors caused by platform transfer—paired with 800kg uniform loading capacity, it maintains stable support for large sheets, reinforcing the machine’s ±0.03mm positioning accuracy. Additionally, the single-platform design streamlines maintenance (e.g., easy access to cutting zones for cleaning) and lowers learning costs for operators, cutting setup time by 15%-20% compared to multi-platform models.

Fully Enclosed Design Enhances Safety & Environmental Control: The full enclosure provides 360° protection against laser radiation (complying with Class IV laser safety standards) and prevents metal dust, smoke, and noise from escaping—reducing workplace noise levels by 25%-30% and eliminating dust pollution. This not only safeguards operator health but also protects surrounding equipment from dust accumulation, extending the service life of workshop machinery. Unlike open-type cutters, it avoids accidental laser exposure risks, making it suitable for workshops with strict safety regulations.

Single Platform + Enclosure Synergy Boosts Efficiency: The single platform enables continuous loading/unloading (with optional external material racks for seamless workflow) while the enclosure maintains a stable internal cutting environment (reducing air turbulence that affects laser focus). This synergy ensures consistent cutting quality even during long-hour operation, and the 100m/min maximum linkage speed paired with the machine’s structural stability allows for high-efficiency processing without compromising safety—ideal for balancing productivity and workplace protection.

|

|

1500W-20000W Sheet Metal Laser Cutting Machine Single Platform Fully Enclosed Images |