| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

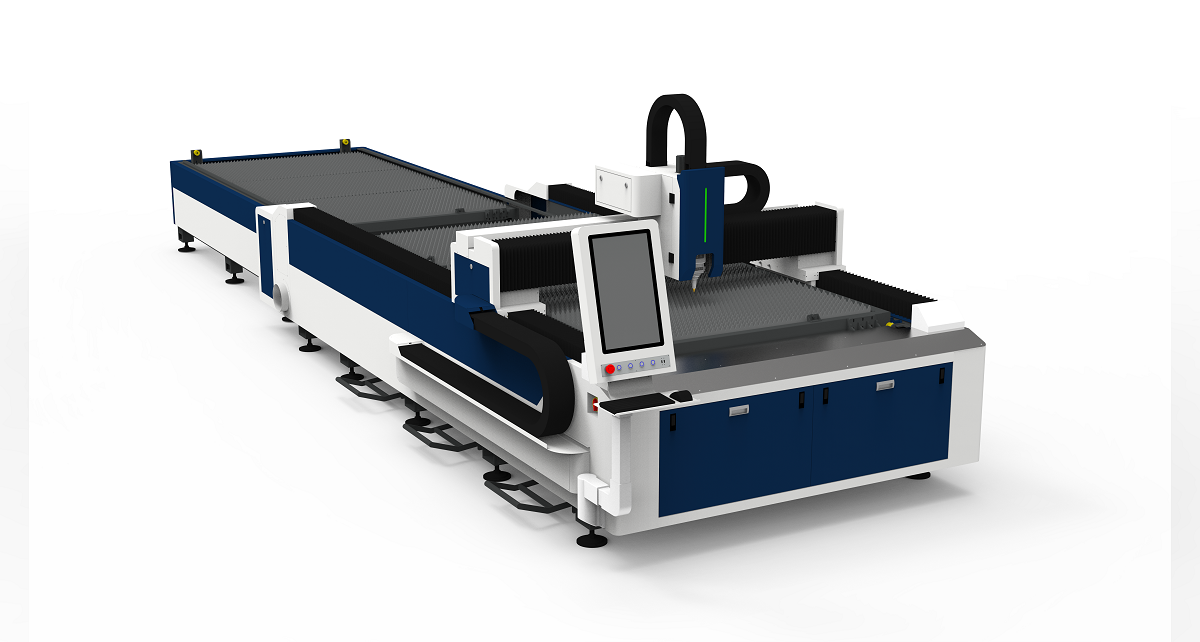

Brand Name : QIHAI

Model Number : QH-3015FA

Certification : CE, ISO

Place of Origin : Foshan, Guangdong, China

MOQ : 1 set

Price : Negotiable

Payment Terms : T/T

Supply Ability : 90set/mon

Delivery Time : 45-60 work days

Packaging Details : wooden box

Product : Sheet Metal Laser Cutting Machine

Processing Area : 3000 * 1500mm

Laser Power : 1500W-20000W

X/Y-axis Positioning Accuracy : 0.03mm

Frequency : 50Hz

Voltage : 380V

Laser Generator Classification : Fiber Laser Generator

Transmission : Double rack&pinion transmission and servo drive

Working Environment : 0-40℃, Humidity ≤80%

Graphic Format : PLT, DXF

Lathe Structure : Tube Sheet Welding

Bevel Angle : ±45°

Beveling Core: ±45° adjustable angle range (0.1° increments) with consistent accuracy; paired with ±0.03mm axis precision for uniform V/U/Y-type bevels.

Key Specs: 3000×1500mm area (1000kg max loading), 6000W-20KW power (0.5-30mm bevel thickness), 100m/min speed, 1.0G acceleration, double rack & pinion transmission.

Dual-Platform & Open-Type: Simultaneous load/cut reduces downtime by 40%; open structure eases heavy workpiece handling for bevel tasks.

Fit: Heavy machinery/steel structures; 380V/50Hz for industrial beveling production.

| Processing Area | 3000 * 1500mm |

| Maximum Loading Weight | 800kg |

| Machine Weight | 1600kg |

| Overall Dimensions | 4800 * 2350 * 1900mm |

| Laser Power Range | 1500W - 20KW |

| X/Y-axis Positioning Accuracy | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.03mm |

| Maximum Linkage Acceleration | 1.0G |

| Maximum Linkage Speed | 100m/min |

| Transmission System | Double rack & pinion transmission with servo drive |

| Voltage Requirement | 380V |

| Beveling Cutting | ±45° |

| Frequency | 50Hz |

Advantage

±45° Beveling Covers Diverse Weld Joint Needs: The ±45° angle range eliminates secondary beveling processes (e.g., grinding/milling) for most weld joint designs—from shallow 5° bevels for thin sheets to steep 45° bevels for thick-plate deep penetration welding. The ±0.03mm axis precision ensures consistent angle across the entire 3000×1500mm workpiece, reducing weld joint misalignment rates by 50% vs. machines with unstable bevel accuracy.

Dual-Platform Synergizes with Beveling Efficiency: Unlike single-platform models that pause for loading/unloading during bevel cutting, the dual-platform design lets operators prep the next workpiece (e.g., positioning thick steel plates for ±45° V-bevels) while the machine cuts—slashing batch processing time by 35%-40%. For 10 pieces of 3000×1500×15mm carbon steel plates needing 30° bevels, total cycle time drops from 2.5 hours (single-platform) to 1.5 hours.

High Speed & Power Ensure Beveling Versatility: The 100m/min maximum linkage speed and 6000W-20KW power range let the machine handle beveling of diverse materials and thicknesses: 6000W for 0.5-10mm stainless steel (fast 80m/min bevel speed) and 20KW for 15-30mm carbon steel (deep, smooth 45° bevels). Even at maximum speed, the double rack & pinion transmission maintains ±0.03mm precision, avoiding bevel edge irregularities common in low-speed, low-power machines.

Open-Type Design Enhances Beveling Practicality: The open structure provides easy access to the processing area, simplifying adjustments for complex ±45° bevel paths (e.g., irregularly shaped steel frames) and enabling quick cleaning of bevel-generated metal chips. It also accommodates custom fixturing for oversized or odd-shaped workpieces needing precise beveling—something enclosed machines struggle with—expanding the machine’s applicability for non-standard bevel tasks.

|

|

Beveling Cutting Dual Platform Open Type Sheet Metal Laser Cutting Machine Images |