| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Brand Name : QIHAI

Model Number : QH-GZ

Certification : CE, ISO

Place of Origin : Foshan, Guangdong, China

MOQ : 1 Set

Price : Negotiable

Payment Terms : T/T

Supply Ability : 100 Set/month

Delivery Time : 50 days

Packaging Details : wood

Control software : Cypcut,Ruida,Perfect Laser Professional Laser Cutting Software,PhotoShop,TAJIMA

Condition : New

Cnc or not : Yes

Graphic format supported : PLT,DXF,AI,BMP,DST

Cutting thickness : Depends,Materials,0-20mm,30mm acrylic,0-15mm

Cooling mode : Water Cooling

Warranty : 1 Year

Laser power : 500W / 1000W / 2000W / 3000W,500-3000W,100W/130W/150W/280W,150W reci,80w/100w/130w/150w

After-sales service provided : Engineers available to service machinery overseas

Color : White,according to client,Required,Blue and white

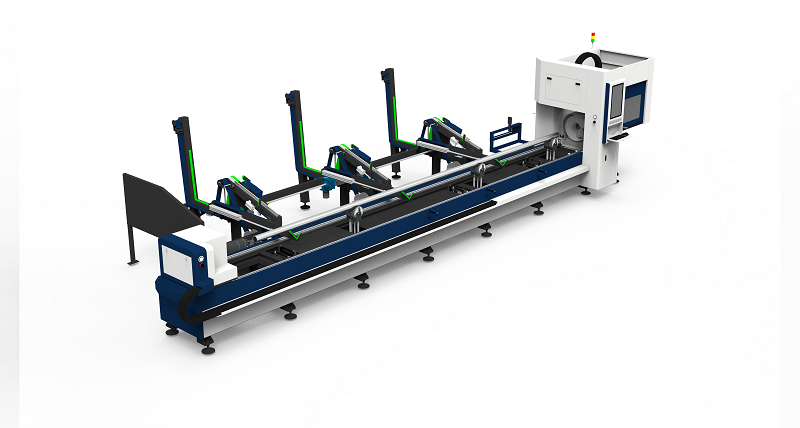

Core Horizontal Beveling Highlights: Horizontally-mounted structure stabilizes Φ15-500mm/15×15-500×500mm tubes; supports ±45° adjustable bevel angles, paired with ≤5mm zero-tailing waste.

Key Specs: 1500W-20KW laser power; ±0.03mm X/Y precision; 5500-6500mm tube length capacity (round/square tubes).

Fit: Weld-ready tube applications (automotive/hydraulic); 2T weight + 9620×2950×2080mm size suits medium workshops.

| Model | QH-GZ |

|---|---|

| Cutting Diameter | Round Tube: Φ15-500mm Square Tube: 15*15mm to 500*500mm |

| Tube Length Capacity | 5500-6500mm |

| Machine Weight | 2T |

| Dimensions (L*W*H) | 9620*2950*2080mm |

| Laser Power Range | 1500W-20KW |

| Positioning Accuracy | ±0.03mm (X/Y-axis) |

| Repositioning Accuracy | ±0.03mm (X/Y-axis) |

| Compatible Tube Types | Round Tube / Square Tube |

Horizontal Layout Guarantees Bevel Angle Consistency: The horizontally-mounted beveling structure aligns tubes parallel to the cutting plane, minimizing gravitational deflection—critical for large-diameter tubes (e.g., Φ500mm round tubes) or long 6500mm tubes. This, combined with ±0.03mm axis accuracy, ensures bevel angle deviation ≤±0.5° across the entire tube length, avoiding weld gaps caused by uneven vertical beveling and reducing rework rates by 40%-50%.

Horizontal Beveling + Zero-tailing Synergy Cuts Costs: The horizontal design maintains tube stability even during the final cut (when residual length is minimized), ensuring the zero-tailing feature’s ≤5mm waste standard is consistently met. For a workshop processing 300 6500mm-long Φ300mm stainless steel tubes monthly, this saves ~380kg of material annually—while the horizontal beveling eliminates secondary angle grinding, lowering labor costs by 25%-30%.

Efficient Beveling for Diverse Tube Types: The horizontal beveling system adapts seamlessly to both round (Φ15-500mm) and square (15×15-500×500mm) tubes. Unlike vertical beveling machines that require complex clamping adjustments for square tubes, the QH-GZ’s horizontal layout uses uniform side clamping to maintain bevel precision across tube shapes—cutting setup time per batch by 30%-35% and boosting daily throughput.

|

|

QH-GZ Zero-tailing Laser Tube Cutting Machine Horizontally-mounted Beveling Cutting Images |