| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

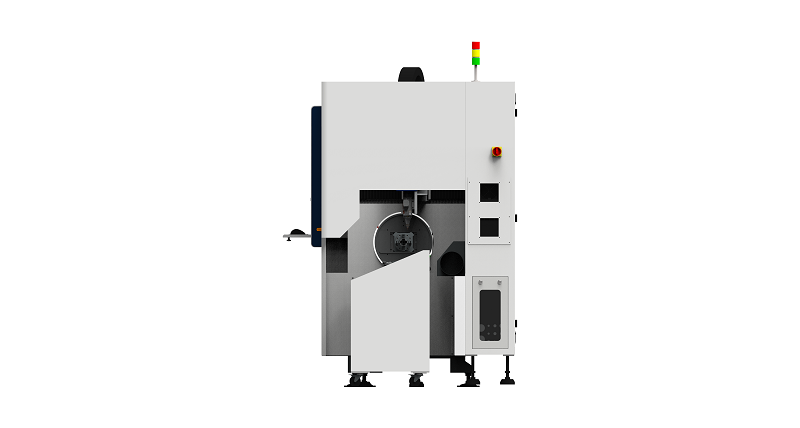

Brand Name : QIHAI

Model Number : QH-GS

Certification : CE, ISO

Place of Origin : Foshan, Guangdong, China

MOQ : 1 Set

Price : Negotiable

Payment Terms : T/T

Supply Ability : 100 Set/month

Delivery Time : 50 days

Packaging Details : wood

Cnc or not : Yes

Graphic format supported : PLT,DXF,AI,BMP,DST

Cutting thickness : Depends,Materials,0-20mm,30mm acrylic,0-15mm

Cooling mode : Water Cooling

Warranty : 1 Year

After-sales service provided : Engineers available to service machinery overseas

Color : White,according to client,Required,Blue and white

Side-mounted Lathe Follow-up Core: Laterally adjusts to 5500-6500mm long tubes; prevents sagging for round (Φ15-500mm) & square (15×15-500×500mm) tubes, maintaining ±0.03mm cutting accuracy.

Key Specs: 1500W-20KW laser power; 8500×1380×2050mm size (1.7T weight); compatible with round/square tubes.

Value: Cuts long-tube setup time by 25% vs. manual supports; reduces sagging-induced scrap rates by 35%.

| Model | QH-GS-6012 |

|---|---|

| Cutting Diameter | Round Tube: Φ15-500mm Square Tube: 15*15mm to 500*500mm |

| Tube Length Capacity | 5500-6500mm |

| Machine Weight | 1.7T |

| Dimensions (L*W*H) | 8500*1380*2050mm |

| Laser Power Range | 1500W-20KW |

| Positioning Accuracy | ±0.03mm (X/Y-axis) |

| Repositioning Accuracy | ±0.03mm (X/Y-axis) |

| Compatible Tube Types | Round Tube / Square Tube |

Sagging Elimination for Long-Tube Precision: For 5500-6500mm long tubes, traditional non-follow-up machines cause 0.5-1mm sagging, leading to cutting deviation. The QH-GS’s side-mounted follow-up system tracks tube movement laterally, adjusting support force at 2-3 dynamic points—keeping the tube straight and ensuring the machine’s ±0.03mm positioning accuracy is maintained throughout full-length cuts or bevels, critical for tight-tolerance applications like hydraulic pipelines.

Versatile Support for Diverse Tube Types/Sizes: The side-mounted follow-up system adapts to round tubes (Φ15-500mm) and square tubes (15×15-500×500mm) without fixture swaps. For small-diameter tubes (e.g., Φ15mm round), it uses low-force, localized support to avoid crushing; for large-diameter tubes (e.g., 500×500mm square), it increases lateral support pressure to counteract weight-induced sagging. This versatility eliminates the need for specialized support tools, lowering equipment costs and simplifying workflow.

Efficiency Boost for Batch Long-Tube Production: Without side-mounted follow-up support, operators spend 10-15 minutes per long tube adjusting manual lateral supports. The QH-GS’s automatic system cuts this setup time to 3-5 minutes, while its stable support reduces rework (from sagging errors) by 40%. For batches of 50+ 6000mm tubes, this saves 4-6 hours of production time, improving overall throughput.

Damage Prevention for High-Value Tubes: Long precision tubes (e.g., automotive chassis tubes) are prone to lateral deformation if supported improperly. The side-mounted follow-up system’s dynamic force adjustment ensures even pressure distribution across the tube’s side—avoiding indentations or bending while maintaining stability. This protects high-value materials, reducing material waste by 25% and enhancing production profitability.

|

|

Water Cooling Tube Cutting Machines Side Mounted Lathe Follow Up Support Images |